Profile in the picture: Teo Baroi

Every work environment has that go-to person. The person you rely on, the one who knows every in and out of the company. The person who gives great advice and the one you can't imagine not being there. In our BMT Group plants, we for sure have a few of these people in our teams. For the BMT Aerospace Romania plant, Teo Baroi is one of these people.

We asked Teo a couple of questions to learn what he thinks about working at BMT Aerospace.

1. Can you explain your job?

On the shop floor, certain processes are implemented to create the parts that we deliver. For this, a lot has to happen; the fixtures, the tools for the parts, the programs in the machines have to be set up, etc. My job as a process engineer is to optimize the work-flow of the processes so we can create the parts as efficient as possible, with minimal loss of material and maximum quality.

2. How long have you been working at BMT Aerospace

I started my career at the BMT Group in 1999 in IGW. In 2003, I made the change to BMT Aerospace.

3. Why did you choose to work for the company?

The complexity and requirements in the aviation industry, such as the precision of the parts are very high. Manufacturing parts for an aircraft comes with a lot of responsibilities. I like to be challenged, and in this industry I am challenged every day.

4. What do you like most about your job?

Other than the challenges, I like that BMT Aerospace gives me the freedom and space to think outside of the box. Whenever I see room for improvement, I get the space and tools to start working on the project.

5. Do you have a personal goal?

Yes, working hard makes people tired. When they are tired, they make mistakes. That is why I want to make the operators' job as easy as possible. To do this, I am creating training programs for operators and engineers. This will allow them to work in the most optimized way with the least possibility to make mistakes.

6. What is the biggest change in the BMT Aerospace Romania plant during your career?

Thanks to evolution of technology and new machines, we are able to manufacture bevel gears. Bevel gears are very hard to manufacture due to the complexity of their shape. BMT Aerospace is one of the few companies in the world that is able to manufacture these complex parts.

TEO'S PROUDEST ACHIEVEMENT

-

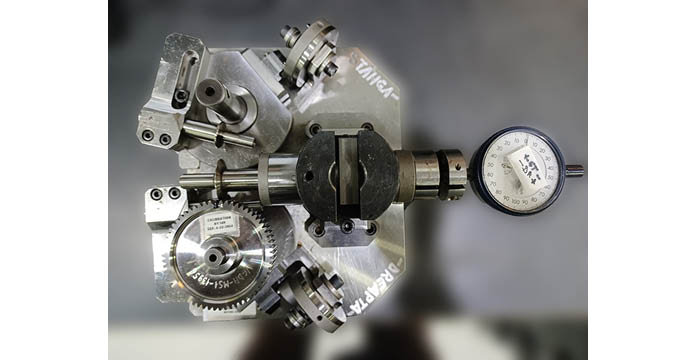

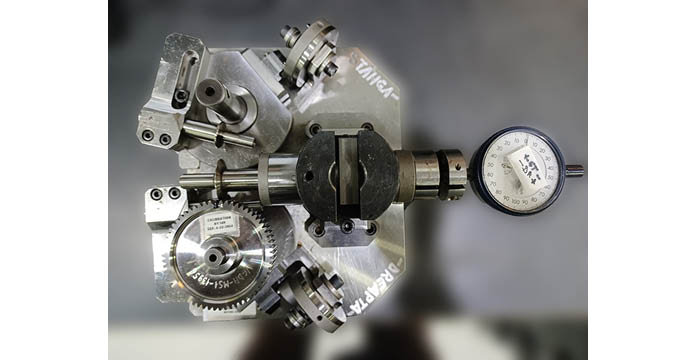

Measuring tool

During his 20 years at BMT Aerospace, Teo has made a lot of improvements in countless manufacturing processes. When asked what he was most proud of, he mentioned this measurement fixture that he created from scratch. This measuring device was created due to the long waiting process during quality measurements. With this device, certain quality factors can be measured in one minute, winning a lot of time in the manufacturing process. It's ideas and improvements like this that make Teo a huge asset for the BMT Aerospace Romania plant.